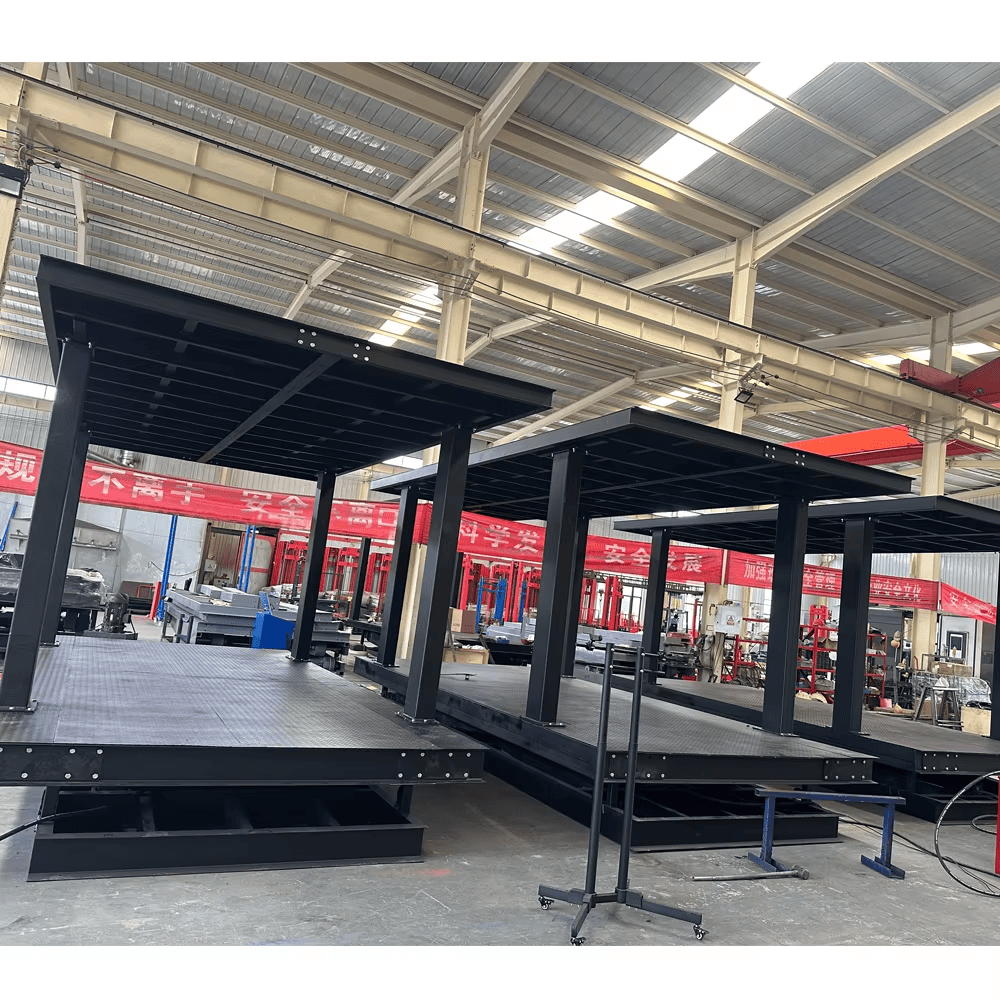

Double-layer scissor lift platform is a mechanical device used for lifting vehicles, which is commonly found in auto repair shops, 4S shops, parking lots and other places. Its core structure adopts a scissor lift mechanism, which has the characteristics of strong stability, large load-bearing capacity and small space occupation.

Underground car elevator or vehicle elevator is an elevator designed for the vertical transportation of vehicles inside buildings, so increasing the number of vehicles that can be parked in parking lots and parking garages. Where real estate is costly, these car parking systems can reduce overall costs by using less land to park the same number of cars

The following is a detailed introduction to the equipment:

I. Structure and working principle

1. Scissor mechanism

– It is composed of multiple layers of cross metal connecting rods (scissor arms) articulated, and the platform is lifted and lowered vertically by hydraulic cylinders or motors.

– The double-layer design (upper and lower platforms) can park two vehicles at the same time, improving space utilization.

2. Power system

– Hydraulic drive: The hydraulic cylinder drives the scissor arm to expand/contract, the lifting is stable, and the load capacity is strong (usually carrying 3-10 tons).

– Electric drive: The motor drives the chain or screw, which is suitable for light vehicles or places with high environmental protection requirements.

3. Platform structure

– Upper platform: lift the vehicle to a high place for easy chassis maintenance.

– Lower platform: fixed or lift Table, used to park the second vehicle or assist in operations.

– Safety guardrail: prevents vehicles from sliding off, some models are equipped with automatic locking devices.

II. Main features

1. Space saving

– Double-layer design enables vertical parking, suitable for places with limited space.

2. Efficient operation

– Can handle two vehicles at the same time (such as upper-level repairs and lower-level maintenance).

3. Safe and reliable

– Multiple safety measures such as anti-fall devices, overload protection, and emergency stop buttons.

4. Flexible configuration

– Can be fixed or mobile, and some models have a rotation function.

III. Application scenarios

1.

IV. Selection considerations

1. Carrying capacity: Select the model according to the vehicle weight (such as 3-5 tons for small cars, and higher for SUVs/trucks).

2. Lifting height: generally 3-5 meters, which needs to be combined with the clear height of the site.

3. Power/hydraulic requirements: Ensure that the site has matching power or hydraulic conditions.

4. Safety certification: Choose products that meet national standards (such as GB/T) or international certification (CE).

V. Maintenance and care

– Regularly check the hydraulic oil level and oil pipe sealing.

– Clean the debris on the scissor arm and lubricate the hinge point.

– Conduct professional safety inspection once a year.